In an era where we demand thinner frames and monstrous performance, a hidden engineering crisis is brewing beneath the aluminum chassis of our favorite devices. You’ve seen the symptoms: a sudden “Black Screen of Death,” GPU artifacts that look like digital rain, or a laptop that simply refuses to wake up.

Most users assume the motherboard is fried. They head to the store to drop $2,000 on a new machine. But here is the industry secret: your hardware isn’t dead. It’s just lost its grip.

The BGA Crisis: High Performance, High Tension

Modern electronics rely on Ball Grid Array (BGA) architecture. Instead of old-school pins, chips like NVIDIA GPUs or Intel Core processors are “floated” on hundreds of microscopic solder spheres.

While BGA allows for blistering speeds and sleek designs, it creates a massive physical vulnerability. Every time you render a video or launch a high-end game, your chip heats up and expands. When you shut it down, it contracts. Over hundreds of cycles, this thermal expansion creates microscopic fractures in the solder. Eventually, the connection snaps. The chip is fine, but the “bridge” of communication is broken.

Enter the Restoration Revolution: More Than Just a “Quick Fix”

The professional electronics restoration industry has evolved into a high-tech frontier. We are no longer talking about simple soldering; we are talking about molecular-level engineering.

For those looking to save their data and their bank accounts, two advanced protocols have become the gold standard:

1. Precision BGA Reflow: The Surgical Reset

When degradation is caught early, technicians use Industrial Infrared (IR) Rework Stations. This isn’t a heat gun in a garage—this is a computer-controlled thermal profile that mimics the original factory assembly line. By heating the board to a precise $217°C$ to $235°C$ (depending on the alloy), the solder reaches a liquidus state, “reflowing” into its original position and sealing micro-cracks instantly.

2. Full BGA Reballing: The Ultimate Resurrection

If the solder has oxidized or suffered “tin whiskers,” a reflow won’t cut it. This is where Reballing comes in—a process as satisfying as it is complex:

- The Extraction: Using vacuum-pickup nozzles and precision thermal shielding, the chip is de-soldered without stressing the surrounding components.

- The Purification: Technicians strip the old, brittle solder using specialized wicks and ultrasonic cleaning.

- The Array Rebirth: Using laser-cut stencils, a fresh grid of high-purity, silver-infused solder spheres is applied.

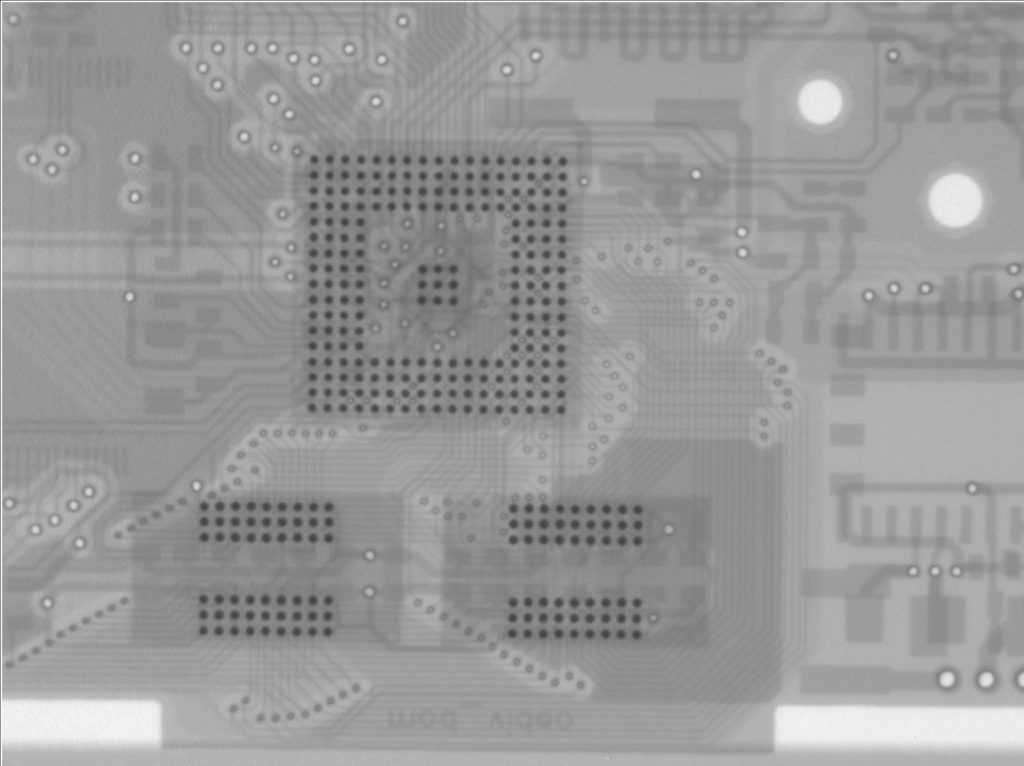

- Optical Alignment: Using “split-vision” camera systems, the chip is aligned with a tolerance of less than 0.05mm before being permanently fused back to the motherboard.

Why This Matters: The $500 Solution to a $2,000 Problem

The economic impact is staggering. A motherboard replacement for a high-end workstation can cost up to 70% of the device’s original value. BGA restoration typically costs a fraction of that, offering a massive ROI for businesses and power users.

But beyond the wallet, there is the Environmental Imperative. We are currently facing a global e-waste crisis. By opting for BGA restoration, you aren’t just saving a laptop; you are preventing rare-earth metals and toxic plastics from hitting a landfill prematurely. A successful reballing can add 3 to 5 years of peak performance to a machine that was destined for the scrap heap.

The Warning: Avoid the “Kitchen Table” Trap

Outbrain readers need to know: BGA repair is not a DIY project. The internet is full of “oven-bake” tutorials that end in disaster. Modern multi-layer PCBs (Printed Circuit Boards) will warp or delaminate if the temperature gradient isn’t controlled by industrial-grade pre-heaters. Without X-ray validation or endoscopic inspection, you’re just guessing.

The Verdict: A New Lifecycle for Tech

The future of tech isn’t just about buying what’s next—it’s about mastering what we already own. As chip designs move toward 3D-stacking and even tighter BGA pitches, the role of the master technician becomes as vital as the original designer.

Don’t let a microscopic crack dictate your productivity. The “dead” laptop in your drawer might just be waiting for a second chance.

This article is provided for general informational purposes only and does not constitute technical instruction, professional advice, or an invitation to perform any repair or modification. BGA restoration procedures carry inherent risks and must only be performed by qualified technicians using appropriate industrial equipment. The author and publisher disclaim any liability for damage, injury, or loss resulting from the use or misuse of this information.